IBC & FIBC Filling Systems

IBC & FIBC Filling Systems

FIBCs (Flexible Intermediate Bulk Containers) also known as Bulk Bags, Tote Bags, Jumbo Bags, Big Bags and Tonne Bags contain between 500kg and 2000kg of product from aggregate and sand to chemical produce and powders. The Sack Filling and Robot Palletising Company offers a solution to fill and weigh the majority of products in varying applications with options designed to offer enhanced simplicity of use, reduced environmental contamination and increased output all incorporating to reduced running costs and down time for the consumer.

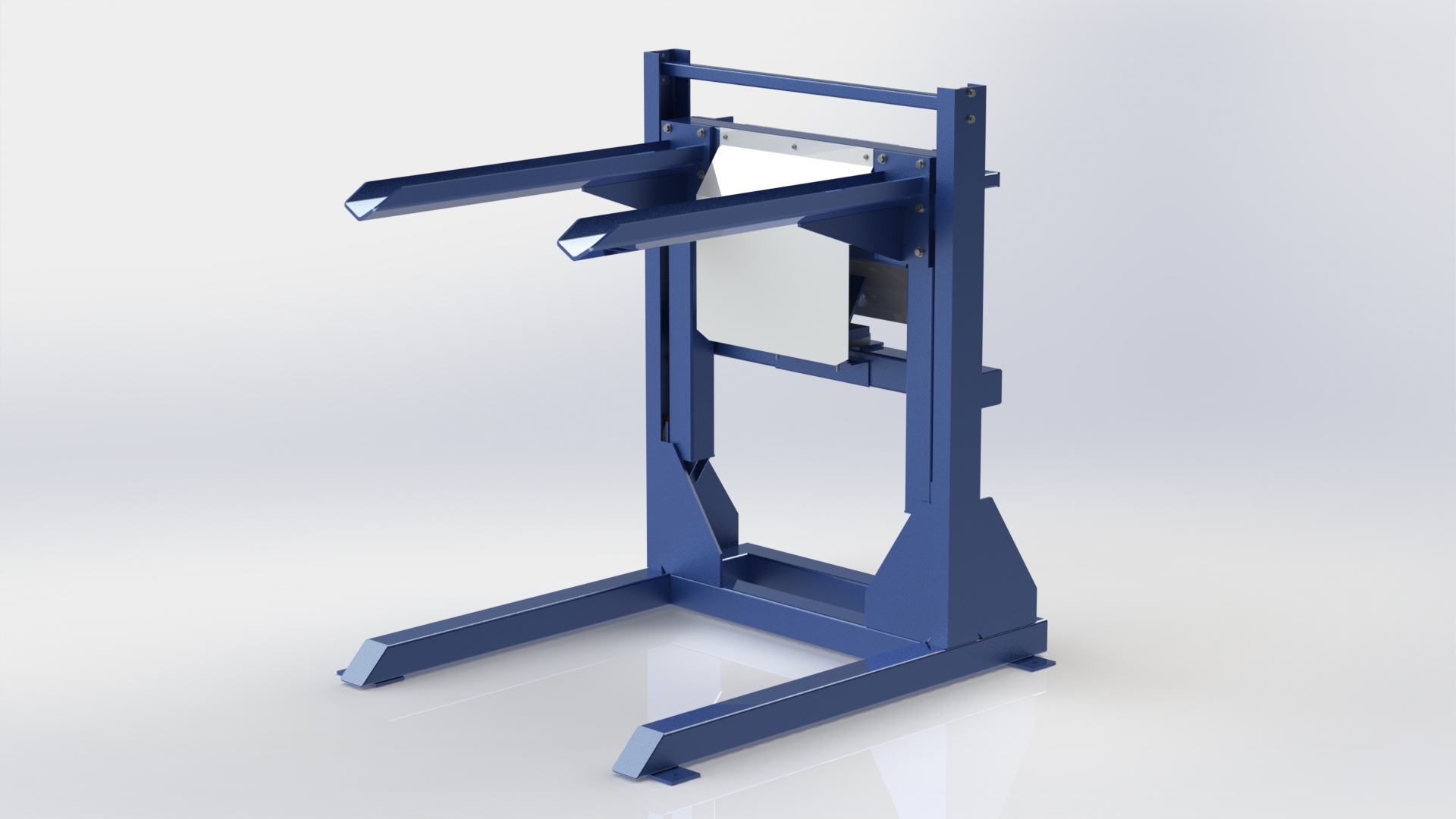

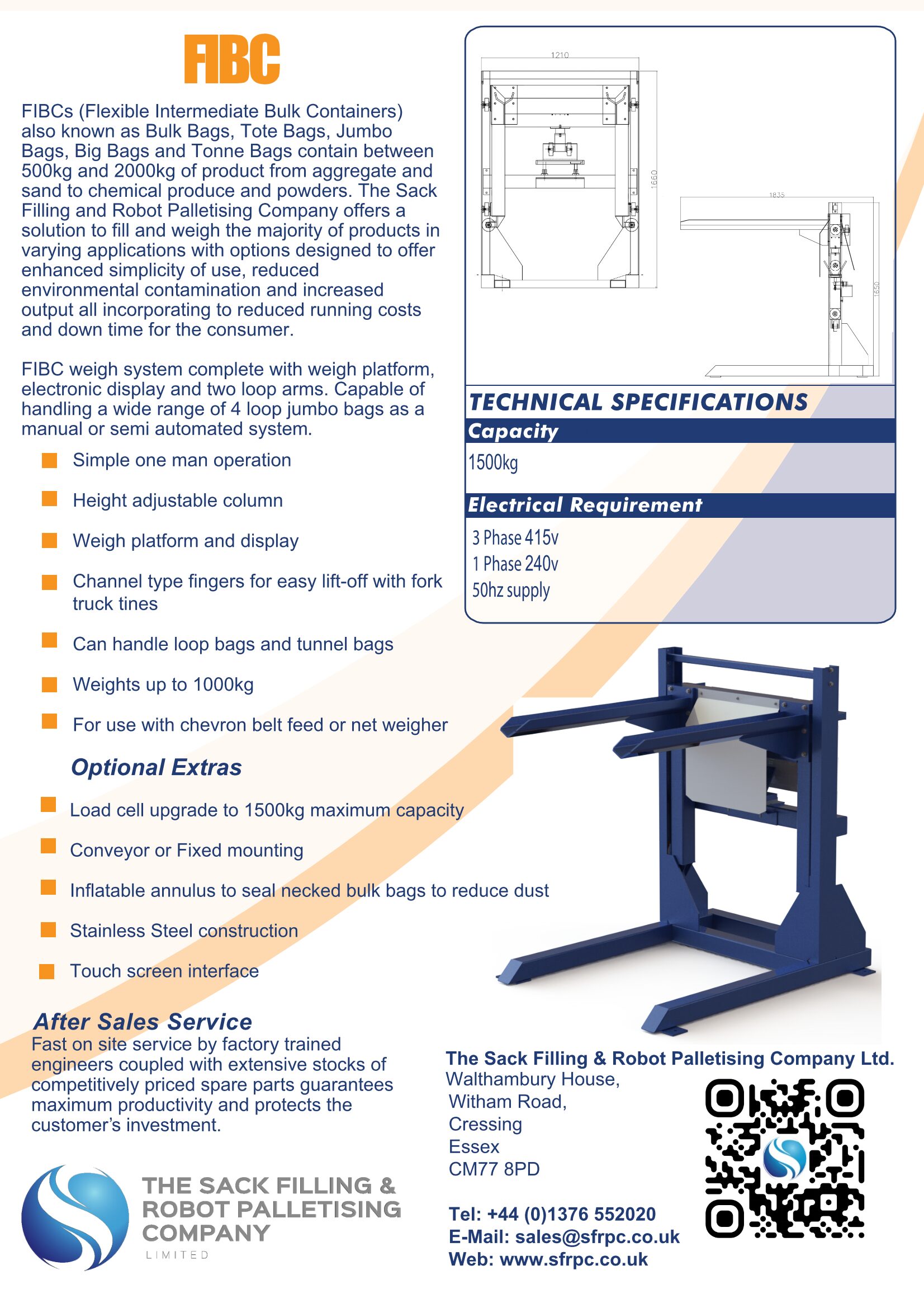

Standard FIBC Filling Unit

Standard FIBC Filling Unit

FIBC weigh system complete with weigh platform, electronic display and two loop arms. Capable of handling a wide range of 4 loop jumbo bags as a manual or semi automated system.

Key Benefits

- Simple one man operation

- Height adjustable column

- Weigh platform and display

- Channel type fingers for easy lift-off with fork truck tines

- Can handle loop bags and tunnel bags

- Weights up to 1000kg

- For use with chevron belt feed or net weigher

Optional Extras

- Load cell upgrade to 1500kg maximum capacity

Conveyor Mounted FIBC / IBC Filling Unit

Conveyor Mounted FIBC / IBC Filling Unit

This special unit is capable of filling different sizes of bulk bag FIBCs with 4 loop fastening. It is incorporated into a semi-automatic system where the bulk bags are hung manually onto the arms, a pallet is indexed into position and the filled bag is then conveyed away on a pallet.

Key Benefits

- Easy one man operation

- Electronic weigh platform and display

- Semi automated system

- 60 tonnes/hr depending on product

- Automatic retracting loop fingers

- Pneumatic rise and fall column

Optional Extras

- Stainless Steel construction

- Touch screen interface

- Inflatable annulus to seal necked bulk bags to reduce dust

Beltyne Big Bag Filling Station

Beltyne Big Bag Filling Station

The Betyne Big Bag Filling Stations are capable of filling large variations in flexible bulk bags with and without inner liners. Manual and fully automated systems are available all are fully dust-proof.

Key Benefits

- During filling the system is dust-tight

- Internal or external product inlet assemblies

- Optional product tamping unit

- Mobile versions available

- Manual loading or electrical hoist with transport facility

- Flexible outlet to suit any existing system or transfer to into many different Beltyne conveying systems i.e. screw conveyors, disc-lifts, pneumatic conveyors etc.

- Minimum maintenance for continuous operation